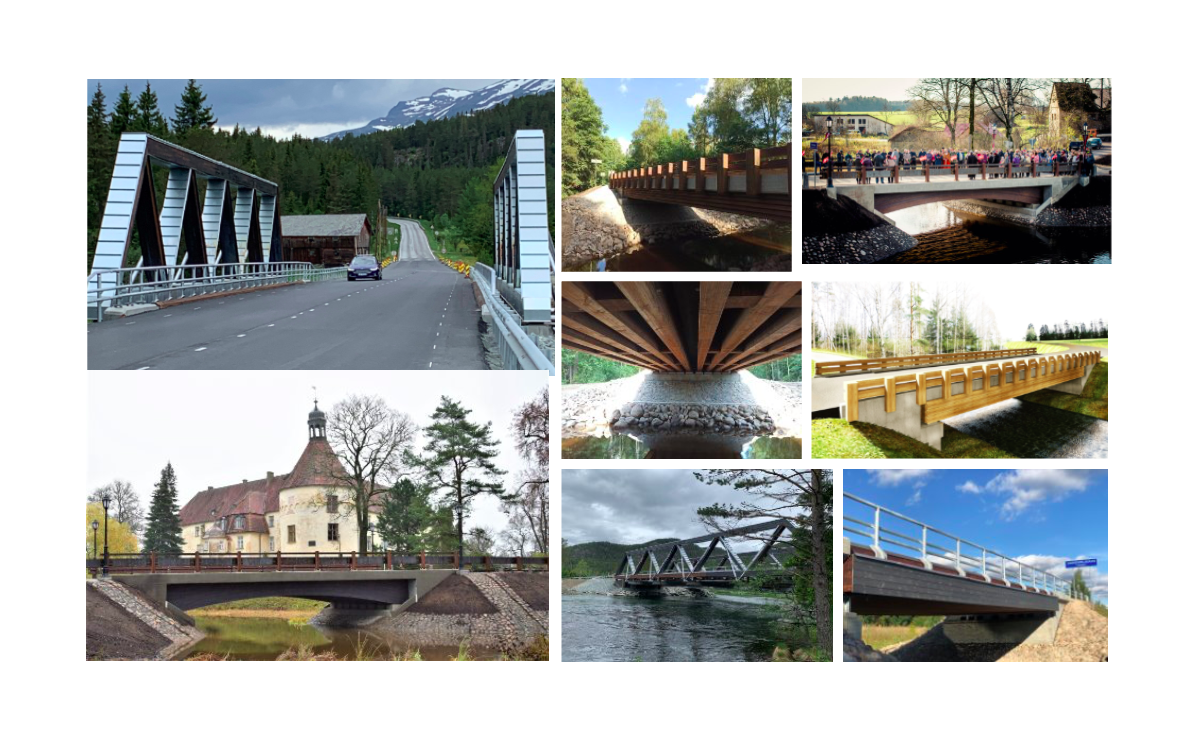

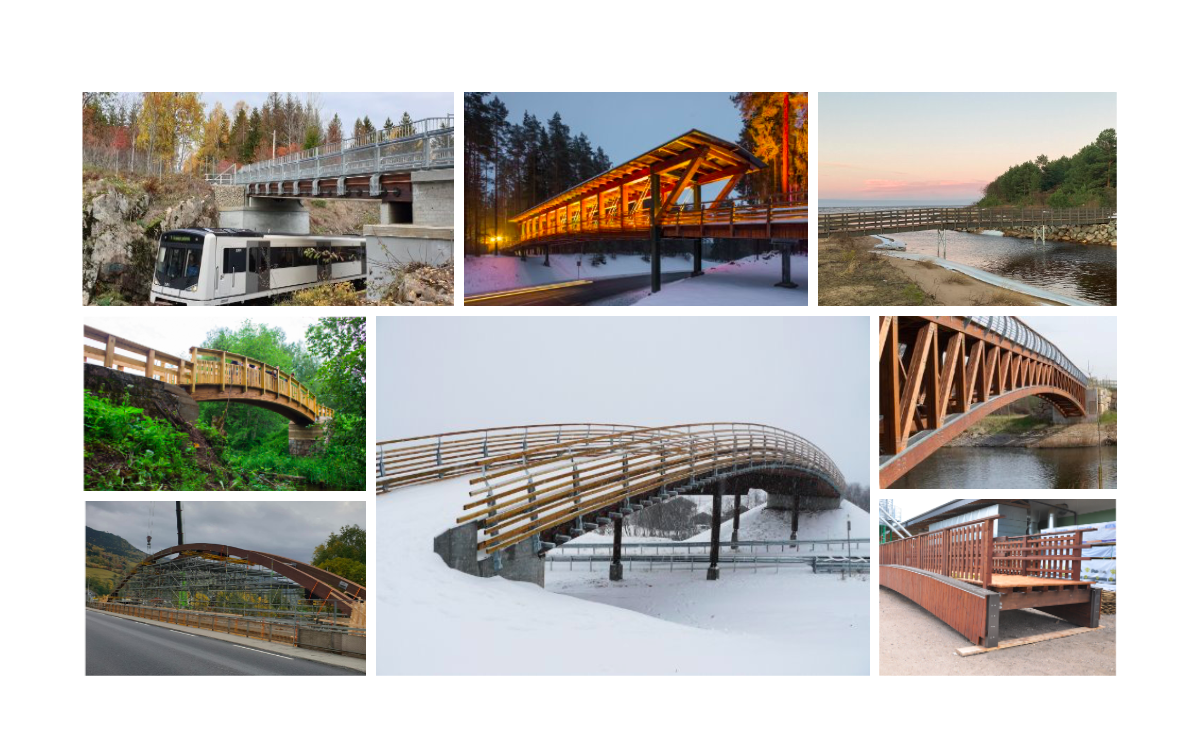

ZAZA TIMBER Production has manufactured glued laminated timber (glulam) structures for transport and pedestrian bridges in Latvia, Norway, Spain, Sweden. In total 35 bridge projects. See our experience and how we can help with your bridge project.

TRAFFIC BRIDGES

OTHER BRIDGES

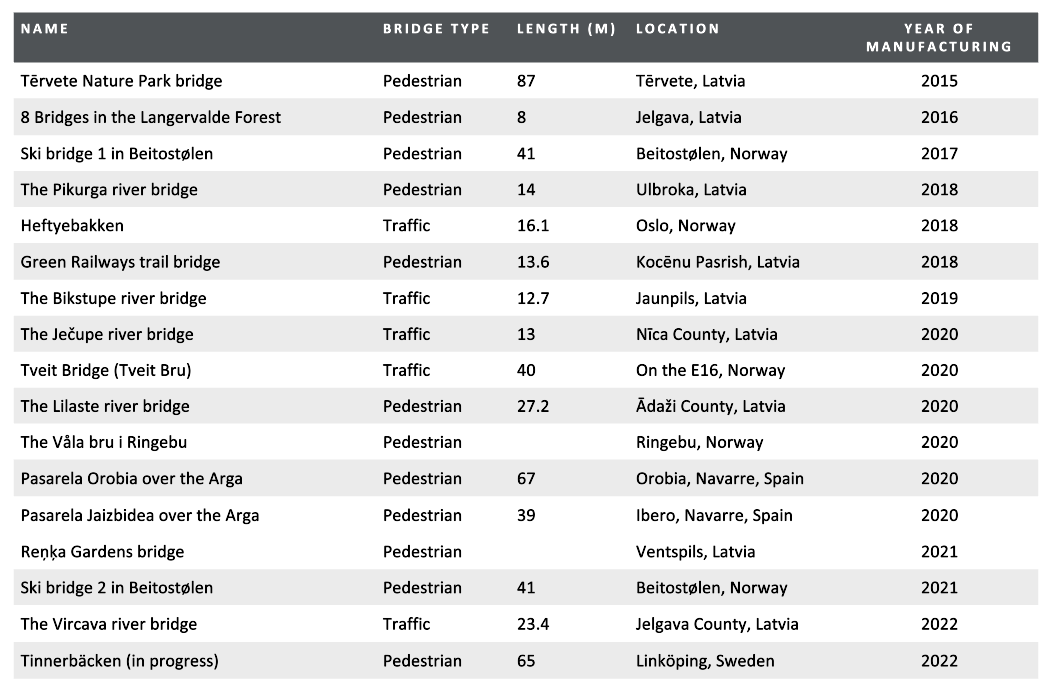

BRIDGES. SELECTED MANUFACTURING PROJECTS (2015-2022)

OUR SKILLS

GLUED LAMINATED TIMBER STRUCTURES WITH LARGE DIMENSIONS

- Up to 32 m long.

- Up to 2.1 m high.

- Block-glued – up to 1 m wide.

- Various strength classes up to GL32.

- Made of spruce, pine, larch.

- EN 14080:2013, FSC.

CURVED GLUED LAMINATED TIMBER STRUCTURES

- Curved structures with constant and variable radi.

- Free-form structures.

- Structures with pre-camber for bridges.

STEEL PARTS INSTALLED

- We deliver pre-fabricated structures with required steel parts included.

- Ordering steel parts.

- Installing steel plates, brackets, angles, shear connectors, dowels, reinforcing rods, screws.

SURFACE TREATMENT

- Single pressure treatment at the required manufacturing stage with required impregnants (fire retardants, antiseptics, creosote).

- Double pressure treatment:

(1) pressure treatment of boards with preservative before gluing;

(2) pressure treatment of finished structures (can include embedded steel parts) with the required preservative (creosote option available). - Various types of manual finishes: oiling, painting, impregnants.

MECHANICAL PROTECTION

- Covering visible drillholes with timber caps for fire safety and visual purposes.

- Arranging the necessary protection made of steel or copper sheets.

LARGE-FORMAT CNC

- High-precision CNC processing: drilling, cutting, milling even for large pieces using TechnoWood and Hundegger equipment.

- We can produce the most complex structures according to computer files using a fully-automated large-format 5-axis CNC eqipment by TechnoWood AG.

AND ... DELIVERY

REFERENCES

TRAFFIC BRIDGES

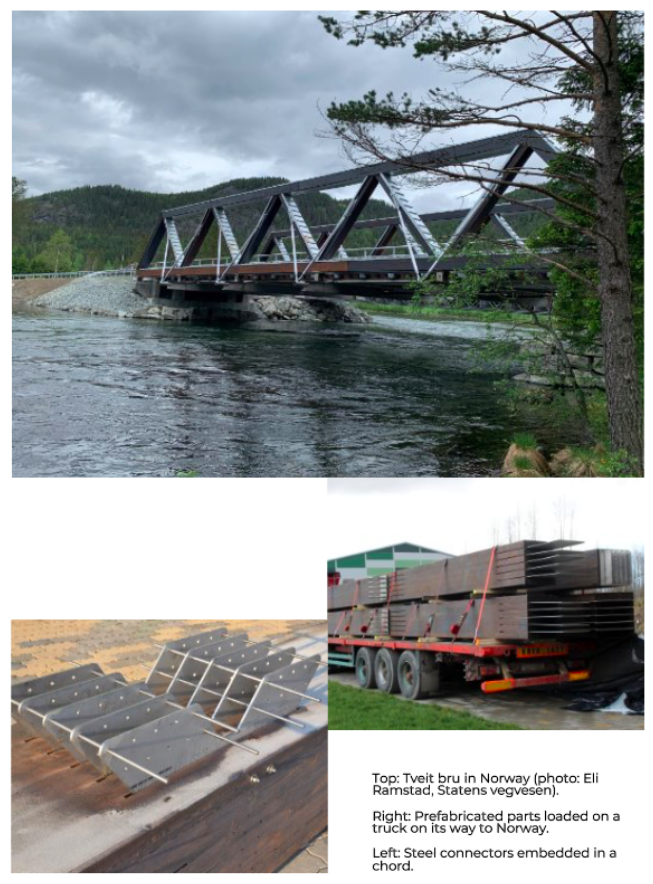

TVEIT BRU IN NORWAY

- Located on the E16, Norway.

- Length 40 m, width 9.5 m.

- We manufactured a full set of timber parts: 211 glulam parts, volume – 252 m3, the longest piece – 27 m.

- Block-glued trusses (top and bottom chord, diagonals). The chords were produced with a camber.

- Ensured high-precision finishes (drilling, sawing) for fastening the steel connectors in parts with huge length and large cross-section.

- Embedded steel parts.

- Arranged pressure treatment twice – before gluing and after gluing.

- Delivered pre-fabricated structures suitable for fast assembly.

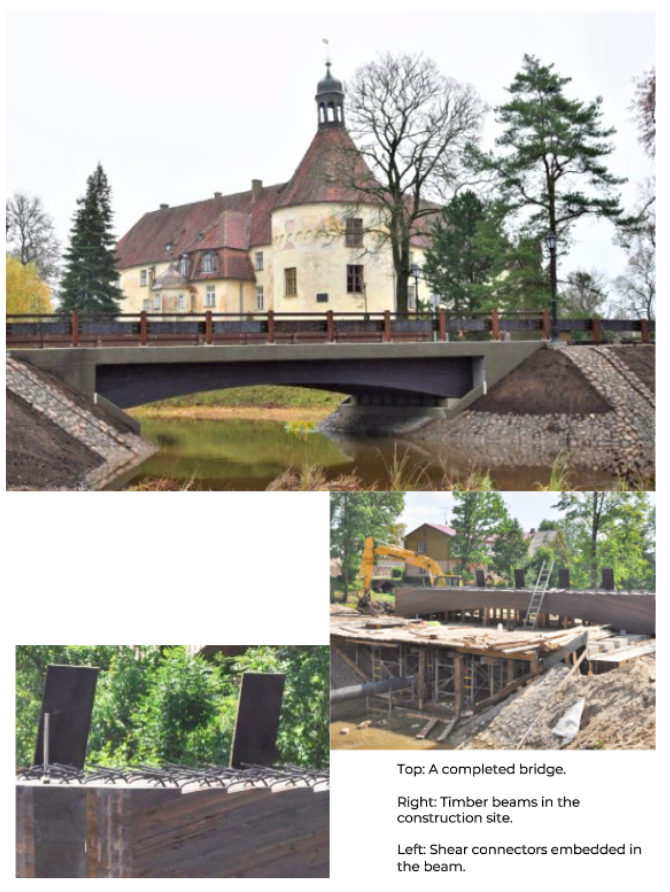

THE VIRCAVA RIVER BRIDGE IN LATVIA

- The bridge has a stress-laminated timber deck.

- Length: 23.4 m, span: 16 m. width 7.9 m.

- We manufactured timber beams (0.115m*0.97m*16.6m) for the deck and timber curb, with strength class GL28h.

- Totally 81 timber pieces with volume 111 m3.

- Pressure treatment twice – before gluing and after gluing.

- The bridge was designed by our group company ZAZA TIMBER Engineering.

THE BIKSTUPE RIVER BRIDGE IN LATVIA

- This is a timber-concrete composite bridge.

- Length: 12.7 m

- We manufactured 8 curved beams with strength class GL32h, length: 11.5 m, variable cross section: 1.35 m at ends, 0.5 m in the middle.

- Total volume: 34.5 m3.

- High-precision finishes, embedding steel elements into timber parts.

- We embedded shear connectors in the beams to ensure composite action between timber and concrete.

- Pressure treatment twice – before gluing and after gluing and embedding shear-connectors.

OTHER BRIDGES

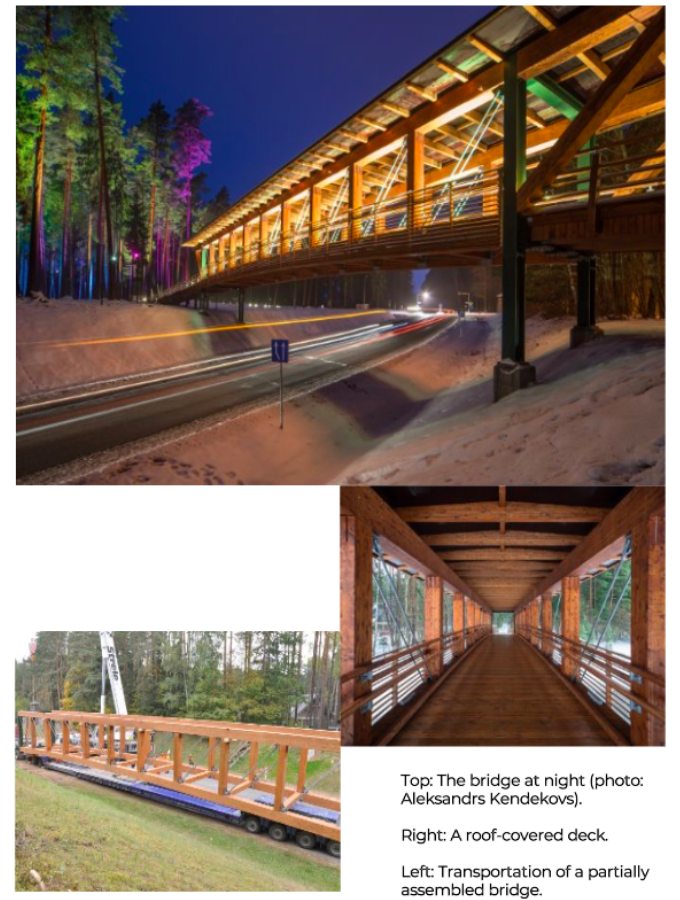

TĒRVETE BRIDGE IN LATVIA

- Length: 87 m.

- We manufactured straight and curved beams, block-glued structures and panels for the bridge truss, cross beams, beams, bridge approach, and roof structure using pine, spruce and larch.

- The total number of parts: 178. Total volume of structures: 97 m3; strength classes: GL28h, GL24c. The longest part was 10.3 m. The largest part was 8.5 m3, the smallest was 1.38 m3.

- Surface treatment with oil for durability.

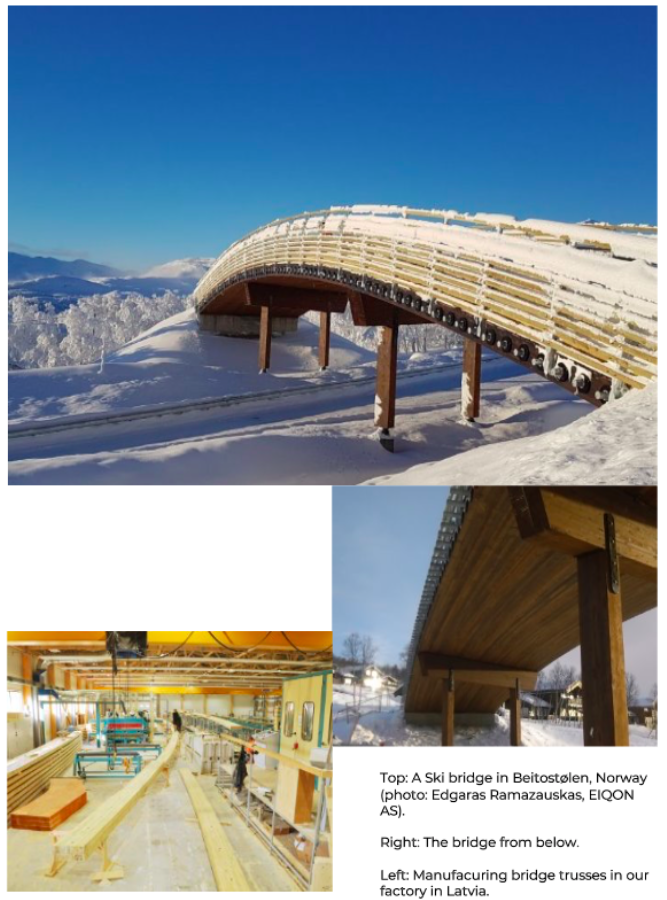

BEITOSTØLEN SKI BRIDGE IN NORWAY

- Length: 41 m, width: 6 m.

- We manufactured a full set of timber parts: straight and curved block-glued parts for the bridge’s truss, cross beams, beams and columns. Total volume: 117 m3, strength class: GL28h. Number of parts: 174; longest part: 16 m.

- We arranged and embedded steel couplings into the parts.

- We arranged pressure treatment twice – before gluing and after gluing.

- Delivered pre-fabricated structures that made fast assembly possible.

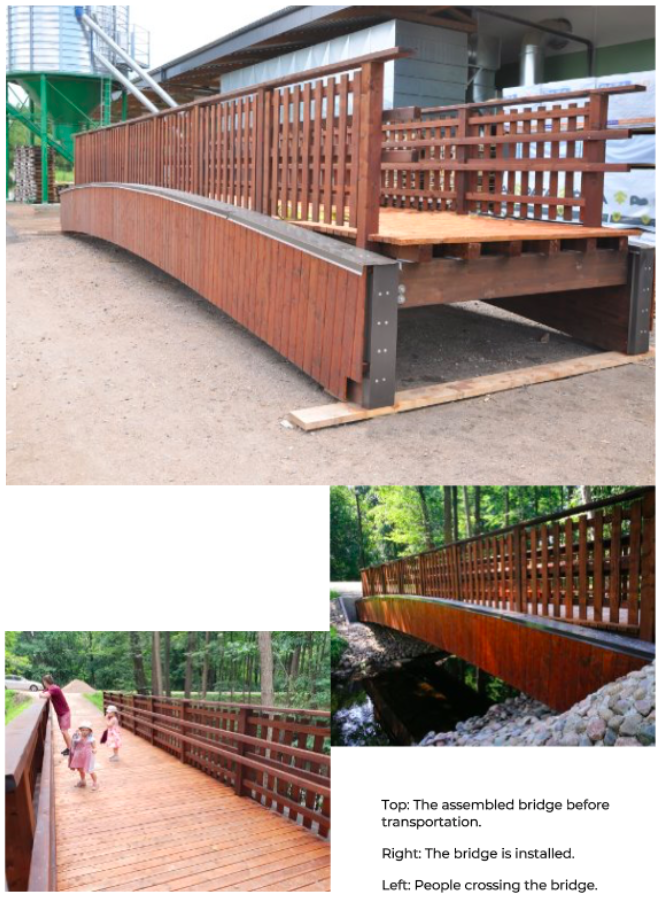

THE PIĶURGA BRIDGE IN LATVIA

- Length 14 m, width 2.5 m.

- We manufactured glulam and other timber parts for the deck, cladding and railings.

- A large variety of parts, totally 633.

- We assembled the entire bridge on the ground of our factory, delivered the bridge to designated location.

- This bridge was designed and assembled by our group companies.

- Design time – 1 month, production time – 2 months, construction time (incl. groundworks – 3 months).

Let's talk about your project!

Mareks Balodis

Head of Sales

T +371 26480828

E sales@zazatimber.lv