A timber bridge designed and manufactured by ZAZA TIMBER over the Vircava in Latvia opened in September 2022. The stress-laminated timber deck (SLTD) is covered with asphalt concrete. The span of the bridge is 16.00 m, providing a bridge without intermediate supports to improve the flow of the river, as well as reduce the formation of ice congestion and river sediments. The total length of the bridge structure is 23.40 m, width: 7.90 m, roadway width: 6.5 m. The bridge is designed to support up to 60 tons load and last at last 100 years. During the construction of the bridge, the existing road bridge was completely dismantled and a new bridge was built.

The shore support is made of monolithic reinforced concrete with 4 CFA type drilling piles with a diameter of 880 mm and a length of 9 m on the right bank and 11 m on the left bank.

The main design works was performed by our engineers Rainers Daugava, Pēteris Supe, Mareks Gindra.

This is the largest stress-laminated timber deck transportation bridge in Latvia and the first this kind of bridge with asphalt concrete wearing surface in the country. Although in Scandinavia these types of timber bridges are designed and built for almost 30 years, there is minimal experience in Latvia. So we used extensively handbooks, publications and reference projects from Sweden and Norway to be able to design and assembly prestressing systems, connections, barriers, asphalt concrete layers, foundations and curbs. Also, waterproof layer and barriers specially made for stress laminated timber deck bridge were available only in Scandinavia.

Bridge engineer Rainers Daugava

Our factory ZAZA TIMBER Production was no stranger to a bridge structure of this type. This was our sixth project, in which we made beams for a stress laminated timber deck; the previous five manufacturing projects were for bridges in Scandinavia.

The load bearing structure of the bridge is a stress-laminated timber deck consisting of 61 glued timber beams (each beam width 115 mm and height 880 to 964 mm) positioned side by side and stressed together using 66 high-strength steel tensioning cables. The glulam beams, made of pine (strength class GL28H), had undergone pressure treatment twice – before and after gluing. Besides chemical protection the stress-laminated timber deck also is protected mechanically – with waterproofing layer under asphaltconcrete and plank cladding with stainless steel sheeting on longitudinal sides. The total glulam volume in this project was 111 m3, the largest parts were 115 x 970 x 16600 mm.

- Commissioned by: Jelgava County.

- Builder: SIA “RĪGAS TILTI”.

- Designer and author’s supervisor: ZAZA TIMBER Engineering SIA.

- Glulam structure manufacturing: ZAZA TIMBER Production SIA.

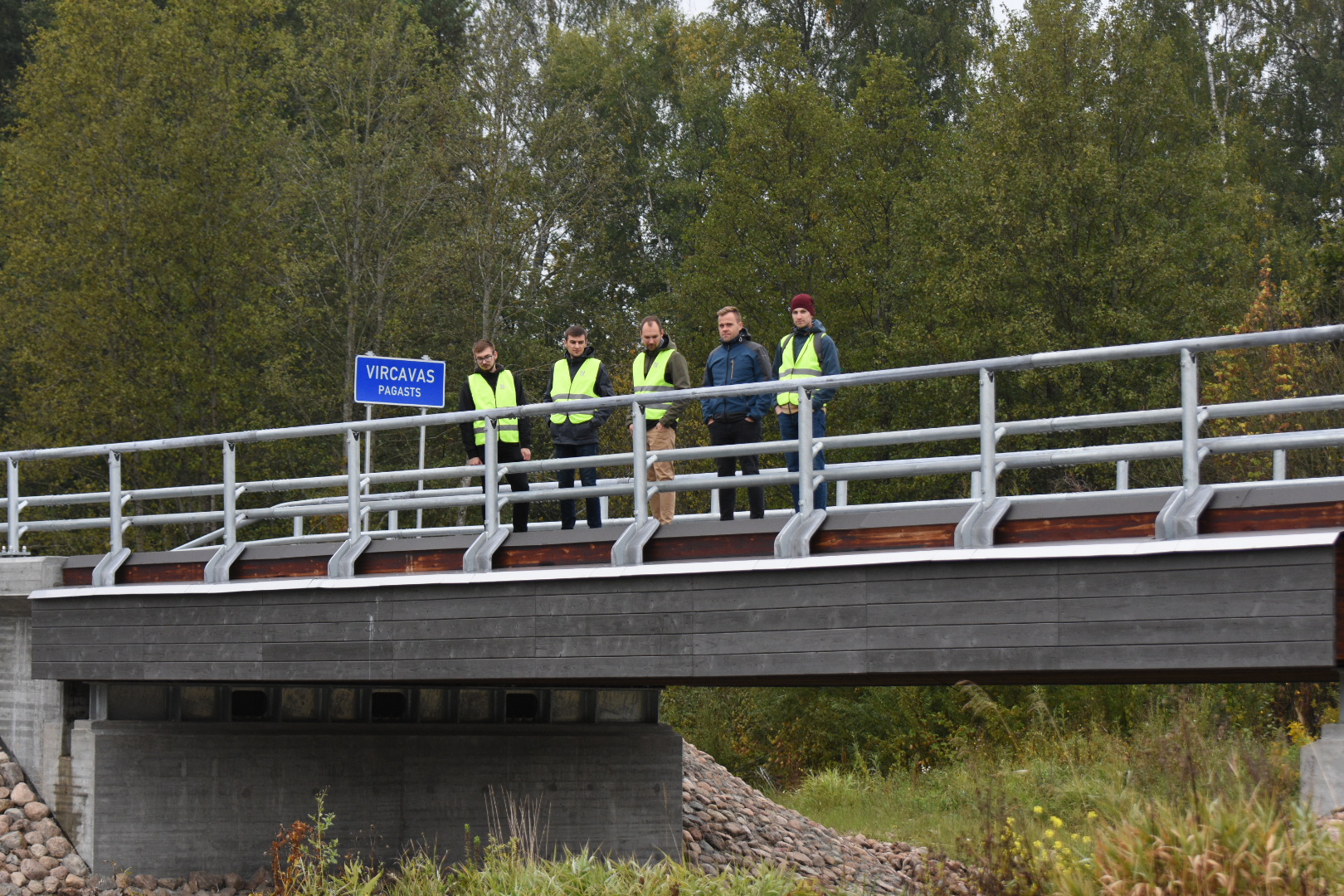

- Structural engineer Mareks Gindra visiting the bridge

- Our engineering team visiting the bridge

- Our engineering team visiting the bridge